Email : info@narainexport.com

The Indian pile carpet history started in the 16th century around 1580 A.D. at the time of Mughal Emperor Akbar, who invited Persian carpet weavers to India and set up workshop in his own palace. Thereafter carpet weaving started in India. The carpet industry is a traditional, rural based highly labour intensive cottage industry. It is an unorganized sector industry providing vast employment.

MAKING OF A CARPET

Traditional skills of some fifth and sixth generation weavers are employed to make exquisite carpet with contemporary trends. The designers create a design based on which trained artists paint a colour plate which is representation of the pattern. Based on the colourplate, a naksha or plan of the design, is plotted on a huge graph paper, each square of which represents one knot. Nakshas are made with colours much brighter than what are eventually used in the Carpet. Each colour on the naksha indicates a specific shade of yarn, enabling the weaver to read the design easily.

The yarn is then dyed and is checked for colour fastness to chemical washes, exposure to light and rubbing. The woollen yarn is tested too for thickness count and non fibre content. The cotton used in the warp of the carpet is tested for its tensile strength, for if this is low,the carpet can tear easily even as it is being woven. At this stage the yarn is made moth resistant. After stringent tests, the yarn ready for weaving is usually carried to the home of the carpet weavers or loom owners.

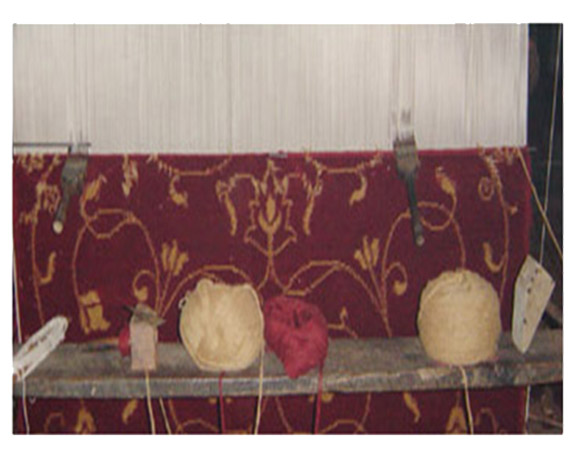

The loom is prepared for weaving a Hand Knotted Carpet by setting 2 rows of warps, that are stretched vertically and closely from the top of the loom to its bottom. The Carpet progresses as knot after patient knot of the woollen yarn on the warps, is tied. This creates the pile of the carpet.

After a row is woven, a thick cotton thread is put between the two rows of warps and is hammered down. This is the first weft which gives the carpet its body. A second weft interlocks the warp strings across each row to keep the knots in place. These are then firmly beaten down to ensure they stay even and tight. This is repeated until the Carpet is entirely woven.

Hand Tufted Carpets are made with tufting gun which punches woollen yarn through a canvas backing which has the design traced on it. This creates the pile of the tufted Carpet. A cotton net is then spread across the back of the Carpet, and latexed to fix the tufts on the fabric. Another layer of latex and canvas gives the back of the Carpet a neat look.

After the weaving or tufting is complete, the process of washing, clipping the excess pile, the colour sorting to clarify the pattern and stretching to ensure symmetry are few of the many stages in the finishing process.The most significant of these is the washing.

Before washing,the carpet goes through the stage of burning with back of the carpet, rubbing with wired brush and berai to make it even.Washing is done with water mixed with soap, bleaching powder and other natural chemicals. After washing,the carpet is kept in the sunlight for drying and then it is sent for clipping. There are wide ranges of washes each of which imparts a different look to the Carpet. Depending upon the Buyer's needs, a Carpet can receive a normal wash,high lustre wash, Gold wash, Herbal Wash or an Antique wash. These add new dimensions to the carpet, some increasing its sheen, some muting its colour and others lending a antique look.

CARPET CARING

The oldest existing carpet dates back to the fifth century B.C. The endurance and longevity of the carpet depends not only the way it is created but also on its regular care.

A regular care routine keeps its charm intact and allows it to age gracefully.

STAIN REMOVAL

The easiest way to remove any stain is to get to it quickly. DO NOT WAIT.

Place a clean, absorbent cloth over the stain.

Always dab - Harsh rubbing could ruin the carpet fibre.

Avoid hot/warm water to clean, this can spread the stain to wider area.

Work inwards from the edge of the stain to prevent spreading.

CLEANING MATERIALS AND PROCEDURES

| STAIN | REMOVAL PROCEDURE |

|---|---|

| Alchohol | Shampoo then dab with methylated spirits |

| Beer | Dab warm water with 5% methylated spirits |

| Ball Point Pen | Use perchlorethylene and methylated spirits |

| Blood | Dampen cloth with soda water, dab clean |

| Butter Oil | Dab with white spirit then shampoo |

| Candle Wax | Cover with blotting paper and go over with a warm iron |

| Chewing Gum | Apply Anti-gum, dab with perchlorethylene |

| Chocolate | Dab with warm water with 5% ammonia |

| Coffe /Tea | Shampoo or dab with methylated spirits |

| Cosmetics | White Spirits then shampoo |

| Eggs | Dab with methylated spirits then shampoo |

| Food Stuffs | Dab with warm water then shampoo |

| Glue Varnish | Apply white spirits, dab with warm water |

| Milk | Shampoo then dab on methylated spirits |

| Mud | Allow to dry, vacuum the hardened pieces |

| Nail Varnish | Dab with acetone then shampoo |

| Paint , Oil | Dab with white spirits then shampoo |

| Paint , Latex | Only use cold water (Consult a specialist) |

| Rust | Use any anti-rust product for textiles |

| Vomit/Urine | Dab with 50% vineger/50% water, then shampoo |

| Wine | Use 50% vineger/50% water, then shampoo |